Expanding Horizons with Long Flex PCBs: Applications in Medical Devices, Quantum Computing, and Beyond

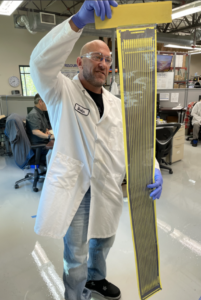

The realm of flexible printed circuit boards (FPCBs) is witnessing a significant transformation with the advent of long flex PCBs, which can extend up to 48 inches in length or potentially longer—far surpassing the traditional panel size limit. This evolution opens up a plethora of opportunities across various industries, notably in medical devices, quantum computing, and other innovative applications.

Medical Devices: Enhanced Functionality and Integration

In the medical sector, long flex PCBs can revolutionize the design and functionality of equipment. These extended-length PCBs are ideal for devices requiring intricate wiring that must fit within confined or irregular spaces, such as wearable health monitors or advanced imaging equipment. By using long flex PCBs, manufacturers can streamline device architecture, reduce bulky wiring, and enhance the reliability and comfort of wearable devices. The inherent flexibility and reduced weight contribute significantly to the portability and durability of medical devices, facilitating new capabilities in patient care and monitoring.

Quantum Computing: Addressing Complex Connectivity Needs

Quantum computing stands at the cutting edge of technology, demanding precise and highly efficient component connections that can operate under critical conditions. Long flex PCBs offer a robust solution by providing reliable, high-density interconnections that can support the intricate and delicate nature of quantum circuits. The ability of long flex PCBs to maintain integrity over longer stretches without compromising performance is crucial in ensuring the stability and reliability required in quantum computing applications.

New Applications: Cost-Effective and Functional Advancements

The potential of long flex PCBs extends beyond current applications, paving the way for innovations across various technology sectors. For example, industries that depend on large-scale sensor networks, such as agriculture or infrastructure monitoring, can benefit from the deployment of long flex PCBs. These circuits can facilitate the integration of sensors and electronics over large areas, significantly reducing complexity and cost while improving system reliability and data accuracy.

Moreover, the automotive industry can leverage long flex PCBs to enhance vehicle design and functionality. Integrating these PCBs can simplify wiring systems, reduce weight, and improve reliability in critical safety systems like airbags and braking systems.

Reducing Costs and Enhancing Performance

One of the most compelling advantages of adopting long flex PCBs is the potential for cost reduction in manufacturing and assembly processes. By reducing the number of interconnects and simplifying the assembly line, long flex PCBs can lower production costs and decrease the likelihood of errors during manufacturing. Additionally, the durability and flexibility offered by these PCBs can lead to longer product lifespans and reduced maintenance costs, delivering a better return on investment.

MicroConnex’s Commitment to Innovation

At MicroConnex, we are actively working on the development of long flex PCBs, pushing the limits of what’s possible in FPCB technology. We welcome the opportunity to collaborate with our customers to develop customized long flex products that meet specific needs and challenges. Our team is dedicated to exploring new possibilities and delivering solutions that enhance product functionality and reduce costs.

Conclusion

As industries continue to evolve, the integration of long flex PCBs could significantly enhance the design and functionality of electronic products, opening up new realms of possibility. MicroConnex is committed to leading this innovation, ensuring our clients can capitalize on the benefits of long flex PCB technology. Whether for medical devices, quantum computing, or exploring new applications, long flex PCBs represent a key innovation in our continued commitment to technological excellence.