Enhancing Flex PCBs with Advanced Electroplating Techniques

Enhancing Flex PCBs with Advanced Electroplating Techniques

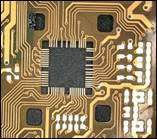

Electroplating is a critical process in the manufacturing of flexible printed circuit boards (FPCBs), significantly enhancing their conductivity, durability, and overall performance. At MicroConnex, we offer a variety of advanced electroplating options to meet diverse application needs, including ENIG, NI/Au, ENPIG, Immersion Sn, and Immersion Ag.

ENIG (Electroless Nickel Immersion Gold): ENIG is widely favored for its excellent surface planarity and long shelf life. This process involves a layer of nickel covered by a thin layer of gold, providing a robust, solderable surface. The gold layer protects the nickel from oxidation, ensuring reliable performance during soldering and component attachment. This combination results in a surface finish that is highly durable and reliable, making it an excellent choice for high-performance applications.

NI/Au (Nickel/Gold): This method, commonly used in high-reliability applications, involves electroplating a nickel layer followed by a gold layer. NI/Au plating offers exceptional corrosion resistance and excellent electrical conductivity, making it ideal for contacts and connectors in flex PCBs. The robustness of this finish is particularly beneficial in harsh environments, where maintaining electrical connectivity and preventing corrosion are paramount.

ENPIG (Electroless Nickel Palladium Immersion Gold): ENPIG combines nickel, palladium, and gold layers, offering enhanced protection against oxidation and corrosion. The palladium layer acts as a barrier, preventing gold from diffusing into the nickel layer, thus maintaining the integrity of the solder joints and ensuring high durability. This makes ENPIG particularly suitable for applications requiring frequent soldering and desoldering, as it maintains excellent joint integrity over multiple cycles.

Immersion Sn (Tin): Immersion Tin is a cost-effective solution that provides a flat, solderable surface ideal for fine-pitch components. It offers good solderability and is an excellent choice for lead-free assembly processes, ensuring reliable performance without the environmental concerns associated with lead-based finishes. The uniform and smooth finish of Immersion Tin is beneficial for high-density interconnects (HDI), where precise soldering is essential.

Immersion Ag (Silver): Immersion Silver is known for its excellent electrical conductivity and cost-effectiveness. This finish provides a smooth, solderable surface, making it suitable for high-frequency applications where signal integrity is crucial. Additionally, it offers good resistance to thermal cycling, ensuring longevity in demanding environments. Immersion Silver’s excellent conductivity and planarity make it ideal for RF applications, where signal loss must be minimized.

Why Choose MicroConnex as Your Flex PCB Manufacturing Partner?

At MicroConnex, we understand the diverse requirements of modern flex PCB applications. Our commitment to delivering high-quality, reliable, and customized solutions sets us apart. We offer a range of advanced surface finish options, including ENIG, NI/Au, ENPIG, Immersion Sn, and Immersion Ag, to ensure your flex PCBs meet the highest standards of performance and reliability. Our expertise in precision manufacturing, combined with our comprehensive electroplating capabilities, makes us the ideal partner for your flex PCB production needs.

We are dedicated to innovation and excellence, ensuring that our manufacturing processes incorporate the latest advancements in technology. Our state-of-the-art facilities and skilled workforce enable us to deliver products that meet the most stringent industry standards. By partnering with MicroConnex, you gain access to a wealth of knowledge and experience, ensuring that your projects are completed efficiently and to the highest quality.

Partner with MicroConnex

With our expertise in precision manufacturing and advanced electroplating techniques, MicroConnex is your ideal partner for flex PCB production. We are committed to delivering high-quality, reliable, and customized solutions that meet your specific requirements. Our focus on innovation and quality assurance ensures that every product we deliver performs reliably in its intended application. Contact us today to learn more about how we can help you achieve the best results for your flex PCB projects. Whether you need the robustness of ENIG, the high conductivity of NI/Au, the durability of ENPIG, or the cost-effectiveness of Immersion Sn and Ag, MicroConnex has the right solution for your needs.