Precision Meets Flexibility: Laser Micro-Machining for Flex PCB Manufacturing

Precision Meets Flexibility: Laser Micro-Machining for Flex PCB Manufacturing

As the demand for smaller, more versatile electronic devices grows, the need for precise and intricate manufacturing processes has become paramount. One such technology that is redefining the landscape of flexible printed circuit board (FPCB) manufacturing is laser micro-machining. At MicroConnex, we leverage this cutting-edge technology to push the boundaries of what’s possible in flex PCB design and production.

Understanding Laser Micro-Machining for Flex PCBs

Laser micro-machining involves using focused laser beams to cut, drill, or engrave materials with exceptional precision. This process is particularly well-suited for flexible printed circuit boards (flex PCBs), where creating fine features and complex patterns is essential. Unlike traditional mechanical methods, laser micro-machining is a non-contact process, which means it doesn’t exert physical stress on the flex PCB material, preserving its integrity and enhancing the overall quality of the final product.

Laser Micro-Machining in Flex PCB Manufacturing:

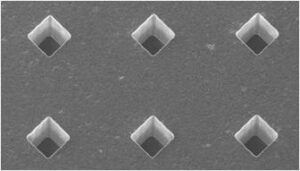

- High Precision and Resolution: Laser micro-machining offers unparalleled precision, enabling the creation of features as small as10 microns on flex PCBs. To put this into perspective, a human hair is typically about 70 microns in diameter. This means that the features we can create with laser micro-machining are roughly one-seventh the width of a human hair. Such an ultra-fine resolution is crucial for the miniaturization trends in electronics, where densely packed components and fine traces are standard. Achieving such tiny feature sizes ensures that even the most complex and intricate designs on flex PCBs can be executed flawlessly. Whether it’s cutting intricate patterns or drilling micro-vias, lasers provide the accuracy needed to meet tight tolerances and ensure the functionality of advanced flex PCBs.

- Versatility with Various Flex PCB Materials: Flex PCBs are often composed of multiple layers of different materials, including polyimide films, copper foils, and adhesives. Laser micro-machining is highly adaptable and can handle these diverse flex PCB substrates efficiently. Its ability to process a wide range of materials without altering their fundamental properties makes it ideal for the complex stack-ups typical in flex PCB designs.

- Enhanced Design Flexibility for Flex PCBs: Withlaser micro-machining, designers are no longer constrained by the limitations of conventional tooling. The precision of lasers allows for greater creativity and complexity in flex PCB design, enabling more innovative and functional electronic products. From curved traces to intricate cutouts, lasers can execute designs on flex PCBs that were previously difficult or impossible to achieve with traditional methods.

- Improved Manufacturing Efficiency for Flex PCBs: The speed and automation capabilities of laser micro-machining significantly enhance manufacturing efficiency for flex PCBs. The process can be easily integrated into automated production lines, reducing cycle times and increasing throughput. Additionally, the precise nature of laser machining minimizes material wastage on flex PCBs, contributing to more cost-effective production.

- Non-Contact Process Ideal for Flex PCBs:One of the most significant benefits of laser micro-machining is its non-contact nature. This aspect is particularly important for delicate flex PCBs, which can be susceptible to damage from mechanical processes. By eliminating physical contact, lasers preserve the material’s properties and reduce the risk of defects, leading to higher quality and more reliable flex PCB products.

MicroConnex: Your Partner in Advanced Flex PCB Solutions

At MicroConnex, we harness the power of laser micro-machining to deliver unparalleled precision and flexibility in flex PCB manufacturing. Our advanced laser systems are capable of performing a wide range of operations on flex PCBs, from fine cutting and drilling to precise patterning and engraving. Coupled with our experienced engineering team, we provide custom solutions that meet the unique needs of our clients in the flex PCB industry.

Collaborative Approach to Flex PCB Design: We work closely with our clients to understand their specific requirements and challenges in flex PCB manufacturing. Our collaborative approach ensures that we provide tailored solutions that not only meet but exceed expectations. Whether you’re developing next-generation medical devices, aerospace components, or consumer electronics, we’re here to help bring your flex PCB vision to life.

Commitment to Quality in Flex PCB Production: Quality is at the core of everything we do. Our laser micro-machining processes for flex PCBs are meticulously controlled and monitored to ensure each project meets the highest standards. This commitment to excellence ensures that our flex circuits perform reliably in the most demanding applications.

Conclusion

Laser micro-machining is transforming the flex PCB manufacturing industry by providing the precision and flexibility needed for today’s advanced electronic designs. The ability to create features as fine as 10 microns—about one-seventh the width of a human hair—opens up new possibilities for the miniaturization and complexity of circuits on flex PCBs. At MicroConnex, we utilize this advanced technology to offer innovative solutions that empower our clients to achieve their goals. Contact us today to explore how laser micro-machining can enhance your flex PCB projects and take your products to the next level.

Ready to take advantage of the precision and versatility of laser micro-machining for your flex PCB designs? Reach out to MicroConnex to discuss your project and discover how we can help you achieve unprecedented levels of performance and reliability in your flex PCB applications.