Ensuring Excellence in Flex PCB Manufacturing: Quality Assurance at MicroConnex

Excellence in Flex PCB Manufacturing: Quality Assurance at MicroConnex

At MicroConnex, the quality of our flexible printed circuit boards (FPCBs) is paramount. To ensure that each PCB meets our high standards, we employ a comprehensive quality assurance process that integrates cutting-edge technology and meticulous testing procedures.

Automated Testing with Flying Probe Machine

A cornerstone of our quality assurance is the use of an automated flying probe machine. This advanced equipment is crucial for testing the continuity of circuits efficiently and accurately. By employing a non-contact method that rapidly tests multiple points on a circuit board, the flying probe machine can identify any potential issues with electrical connectivity without the need for a physical test fixture. This process not only speeds up the testing phase but also reduces the risk of damaging the delicate circuits on FPCBs.

Automated Dimensional Verification

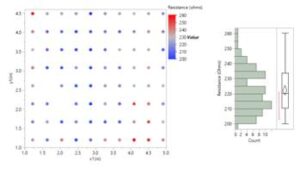

To complement our electrical testing, we utilize automated dimensional verification systems. These systems provide high-precision inspection capabilities that ensure all physical dimensions of our PCBs adhere strictly to design specifications. By catching even the smallest deviations, we can guarantee that every batch of FPCBs meets both our standards and the exacting requirements of our clients.

Laser Removal of Shorts Detected During Inspection

If any shorts are detected during the inspection process, our facility is equipped with state-of-the-art laser technology to address these defects promptly. The precision of laser removal allows us to correct faults with minimal impact on the surrounding circuitry, thereby maintaining the integrity and functionality of the entire board.

Optical CMM with Exceptional Accuracy

Further enhancing our quality assurance capabilities is the optical Coordinate Measuring Machine (CMM). This sophisticated equipment boasts linear accuracy up to 5 microns and Z-axis accuracy up to 3 microns. Such high-resolution measurements are critical in ensuring that every aspect of our FPCBs is produced with absolute precision, from the placement of components to the alignment of layers.

Commitment to Quality

The integration of these advanced testing and correction technologies underscores MicroConnex’s commitment to quality. By continually investing in the latest quality assurance technologies, we not only adhere to industry standards but often exceed them, ensuring that our clients receive products that are reliable, durable, and precise.

Conclusion

Quality assurance at MicroConnex is not just a process; it’s a cornerstone of our manufacturing philosophy. From automated flying probe testing to precise dimensional verification and laser correction, every step in our production is designed to ensure that the FPCBs we produce stand up to the demands of the most critical applications. Our approach is proactive, meticulous, and always evolving, reflecting our commitment to excellence and customer satisfaction.

By choosing MicroConnex for your flex PCB needs, you are partnering with a company that places quality at the forefront of its operations, ensuring that every product not only meets but exceeds expectations. Whether for medical devices, aerospace components, or consumer electronics, our PCBs are built to perform flawlessly in any application.